Industrial Roofing UK: Specialist Roof Repairs, Maintenance and Coatings

Industrial Roofing UK specialise in providing top-tier industrial roofing services across the UK. We offer a full range of services including; roof repairs, maintenance, gutter lining, coatings, cut edge corrosion treatment, the encapsulation of asbestos roofing and surveys. Our commitment to “Future-Proof Industrial Roofing, Built To Last” ensures we employ advanced techniques and premium materials to deliver robust and dependable roofing systems. With a focus on quality and personalised solutions, we manage every project with precision and care, protecting your industrial property. Trust Industrial Roofing UK for the highest standards of service and enduring protection.

Industrial roofing refers to the installation, maintenance, and repair of roofing systems for industrial buildings. Industrial roofs are built to endure harsh environmental conditions, heavy loads, and exposure to chemicals. Industrial roofing utilises robust materials and advanced methods to ensure the longevity and efficiency of the roof. Proper industrial roofing is crucial for safeguarding the building's operations and ensuring the safety of its occupants, providing peace of mind and reliable protection.

Table Of Contents

- What Is Industrial Roofing?

- What Are The Different Types Of Industrial Roofing Services?

- What Is The Difference Between Industrial Roofing And Commercial Roofing?

- What Are The Different Types Of Industrial Roof?

- How Much Do Industrial Roofing Services Cost?

- Our Industrial Roofing Services

What Is Industrial Roofing?

Industrial roofing refers to the installation, maintenance, and repair of roofing systems designed specifically for industrial buildings. Industrial roofs are built to endure harsh environmental conditions, heavy loads, and exposure to chemicals, making them suitable for factories, warehouses, and other large-scale facilities. Industrial roofing employs sturdy materials such as metal panels, single-ply membranes, and bitumen to ensure durability and longevity. Advanced methods are used to enhance the roof's performance, including waterproofing, insulation, and corrosion protection. Quality industrial roofing is crucial for safeguarding the building's operations, ensuring the safety of its occupants, and maintaining energy efficiency. Regular maintenance and timely repairs are essential to extend the roof's lifespan and prevent costly disruptions. Industrial roofing plays a vital role in protecting and preserving the integrity of industrial buildings.

Have a question about an upcoming project?

What Are The Different Types Of Industrial Roofing Services?

The different types of industrial roofing services include installation, repair, maintenance, gutter lining, roof coatings, cut edge corrosion treatment, and roof surveys. Each service is designed to address the specific needs and challenges of industrial roofs, ensuring they remain robust and efficient. These specialised services help maintain the integrity, safety, and functionality of roofing systems in industrial buildings. Together, they provide comprehensive solutions to protect and preserve the overall health of industrial facilities.

- Industrial Roof Installation

- Industrial Roof Repair

- Industrial Roof Maintenance

- Industrial Gutter Lining

- Industrial Roof Coatings

- Cut Edge Corrosion Treatment

- Industrial Roof Surveys

1. Industrial Roof Installation

Industrial roof installation involves the complete setup of new roofing systems using durable materials such as metal panels, single-ply membranes, and bitumen to ensure long-lasting protection and performance. Metal panels and single-ply membranes are favoured for their resilience and capacity to endure harsh environmental conditions. Correctly installed industrial roofs can last over 30 years with minimal upkeep, offering significant cost savings over time. Using high-quality materials and advanced installation methods ensures the roof's durability and efficiency, protecting the building's operations and structural integrity. With the right expertise, industrial roof installation not only provides robust protection but also peace of mind for years to come.

2. Industrial Roof Repair

Industrial roof repair involves addressing issues such as leaks, cracks, and structural damage in the roofing systems of industrial buildings to restore their functionality and integrity. Timely repairs using quality materials like sealants and metal patches are essential to maintain the roof's durability and performance. Properly conducted repairs can extend a roof's lifespan by up to 25 years, significantly reducing long-term upkeep costs. Using advanced repair methods ensures the roof remains waterproof and structurally sound, safeguarding the building's operations and interior. With professional expertise, industrial roof repair not only restores functionality but also ensures ongoing protection and reliability, giving you peace of mind and security.

3. Industrial Roof Maintenance

Industrial roof maintenance involves the regular inspection, cleaning, and upkeep of roofing systems in industrial buildings to ensure they remain in optimal condition. Routine maintenance is crucial for identifying potential issues early and preventing costly repairs. Roofing experts often state well-maintained roofs can last up to 50% longer. The cost saving on an industrial roof which last longer will significantly reducing overall expenses. Regular industrial roof maintenance tasks include checking for leaks, clearing debris, and ensuring proper drainage, all of which contribute to the roof’s longevity and performance. By investing in professional upkeep services, you can ensure your industrial roof remains robust and efficient, providing dependable protection for your facility and peace of mind.

4. Industrial Gutter Lining

Industrial gutter lining involves installing protective layers inside gutters of industrial buildings to prevent leaks and corrosion, ensuring efficient water drainage. Correctly lined gutters are essential for maintaining the structural integrity of a building by directing water away from the roof and walls. Lined gutters can significantly extend the lifespan of a guttering system. This reduces maintenance costs and prevents water damage. Regular inspections and upkeep of gutter linings ensure they remain effective and in good condition. Investing in professional gutter lining services provides dependable drainage, safeguards your building, and offers peace of mind.

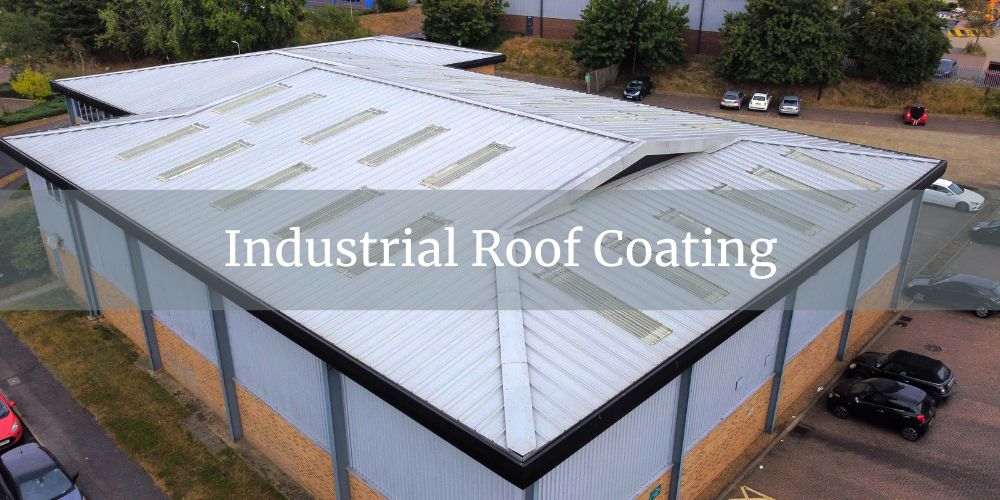

5. Industrial Roof Coatings

Industrial roof coatings involve applying protective layers to the surface of industrial roofs to enhance their durability and performance. Industrial roof coatings can also be applied to vertical surfaces such as wall cladding, for such situations a thixotropic coating is recommended. Industrial roof coatings help prevent leaks, resist weathering, and protect against UV damage and corrosion. Another benefit of industrial roof coatings is they can be used to encapsulate asbestos roofing systems. The process of asbestos encapsulation can prevent a costly and disruptive asbestos roof removal whilst greatly extending the roofs service life. Industrial and commercial properties with roofs treated by high-quality coatings can see the lifespan of their roofing system last up to 20 years longer. This means industrial roof coatings significantly reduce maintenance expenses. Industrial roof coatings can improve energy efficiency by reflecting sunlight, which lowers rooftop temperatures and reduces cooling costs. By using advanced materials and methods, industrial roof coatings ensure the roofs of industrial and commercial properties remains in excellent condition, safeguarding their interiors and preventing disruption to operations.

6. Cut Edge Corrosion Treatment

Cut edge corrosion treatment involves addressing the deterioration at the exposed edges of metal roofing sheets where the protective coating has degraded. According to leading cut edge corrosion expert Andrew Bright, “early detection and treatment are essential to prevent extensive damage and expensive repairs”. The process of cut edge corrosion treatment includes; cleaning the affected area, removing rust and loose coatings, then applying a high-quality sealant or coating to protect the exposed metal. A reliable cut edge corrosion method is to apply a liquid polyurethane coating which provides durable protection and helps restore the roof's integrity. Investing in professional treatment ensures the longevity and functionality of your roofing system, offering peace of mind and safeguarding your investment.

7. Industrial Roof Surveys

Industrial roof surveys involve thorough inspections of roofing systems in industrial buildings to assess their condition and identify potential problems. Regular surveys are crucial for early detection of issues such as leaks, structural damage, and wear, preventing expensive repairs. The process generally includes visual inspections, moisture detection, thermal imaging, and detailed reports outlining the roof’s status and recommended actions. These assessments ensure the roof remains functional and safe, extending its lifespan and maintaining the building’s operational integrity. Investing in professional roof surveys provides reassurance, knowing your roofing system is well-maintained and protected against potential failures.

What Is The Difference Between Industrial Roofing and Commercial Roofing?

Industrial roofing and commercial roofing differ primarily in the nature of the buildings they serve and their specific requirements. Industrial roofing is designed for facilities like factories, warehouses, and manufacturing plants, which often handle heavy machinery, chemicals, and extreme conditions. Industrial roofs must be highly durable and resistant to corrosion, heavy loads, and environmental hazards. Materials such as metal panels, single-ply membranes, and bitumen are commonly used for their strength and longevity.

In contrast, commercial roofing is tailored for buildings like offices, retail stores, and leisure centres. In commercial roofing projects factors such as; aesthetic appeal, energy efficiency, and accommodation of HVAC systems are more important. Materials such as TPO (thermoplastic polyolefin), EPDM (ethylene propylene diene terpolymer), and cold-applied liquid systems are frequently used for their flexibility and cost-effectiveness.

Industrial roofing often requires specialised treatments like cut edge corrosion prevention and more intensive maintenance routines to ensure the roof can withstand harsh operational conditions. Commercial roofing, while still requiring regular maintenance, generally face less severe conditions and thus have different upkeep needs. Overall, the distinction between industrial and commercial roofing hinges on the specific demands of the building's function and its operating environment.

What Are The Different Types Of Industrial Roof?

The different styles of metal roofs for industrial buildings in the UK include standing seam metal roofs, corrugated metal roofs, ribbed metal roofs, flat metal roofs, and insulated metal panels. Each type offers unique benefits suited to various industrial needs and environmental conditions. Understanding the specific advantages of each style helps in selecting the most appropriate roofing solution for your industrial building.

- Standing Seam Metal Roofs

- Corrugated Metal Roofs

- Ribbed Metal Roofs

- Flat Metal Roofs

- Insulated Metal Panels

1. Standing Seam Metal Roofs

Standing seam metal roofs feature vertical panels with seams that rise above the surface of the metal roofing. The primary benefit of this design is its exceptional durability and weather resistance, which is crucial for the UK's variable climate. Standing seam metal roofs can last over 50 years with proper maintenance, providing a long-term, cost-effective solution. The raised seams are crimped or mechanically seamed to ensure superior waterproofing, making them highly effective in preventing leaks and water damage. This style is ideal for industrial buildings requiring robust protection against harsh environmental conditions, ensuring the roof remains resilient and dependable.

2. Corrugated Metal Roofs

Corrugated metal roofs are characterised by their repetitive wave-like pattern. The main advantage of this design is its high durability and excellent drainage properties, making it particularly effective for industrial buildings exposed to harsh weather conditions. Corrugated metal roofs can last over 30 years with minimal upkeep, providing a dependable and long-lasting roofing solution. Their lightweight nature also makes installation simpler and more cost-effective, while the wave pattern adds structural strength, enhancing the roof's ability to withstand heavy loads and environmental stress. This style is ideal for industrial settings, offering a robust and efficient option for roofing.

3. Ribbed Metal Roofs

Ribbed metal roofs are similar to corrugated roofs but feature ribs spaced further apart. The primary advantage of this design is its enhanced strength and rigidity, making it ideal for large industrial structures. Ribbed metal roofs offer excellent load-bearing capacity and can endure extreme weather conditions. The wider rib spacing not only adds to the structural integrity but also improves the roof’s aesthetic appeal. Ribbed metal roofs are a practical choice for warehouses and large manufacturing facilities, providing a durable and economical roofing solution, ensuring long-term performance and reliability.

4. Flat Metal Roofs

Flat metal roofs are used in industrial settings where low-pitch or flat roof designs are required. The main benefit of this design is its practicality for space utilisation and equipment housing. Flat metal roofs are designed to handle slight slopes for drainage and need robust waterproofing techniques to prevent leaks. This style is particularly beneficial for industrial buildings where maximising rooftop space for HVAC systems or solar panels is essential. Flat metal roofs offer a durable, efficient solution that ensures the roof remains functional and resilient in various environmental conditions, providing reliable protection and versatility.

5. Insulated Metal Panels

Insulated metal panels consist of metal sheets with an insulating foam core, offering excellent thermal performance and structural strength. The primary benefit of these panels is their superior insulation, making them ideal for temperature-sensitive industrial environments.Insulated metal panels can improve energy efficiency by up to 30%, significantly reducing heating and cooling costs. These panels are commonly used in industrial buildings like cold storage facilities and food processing plants, where maintaining strict temperature control is essential. Insulated metal panels provide a durable, energy-efficient solution, ensuring your building remains well-protected and climate-controlled. Their versatility and effectiveness make them a top choice for industries requiring stringent climate management and robust structural integrity.

How Much Do Industrial Roofing Services Cost?

The cost of industrial roofing services is between £46.00 and £164.00 per square metre (SQM) in most cases. However, prices will vary depending on the industrial roofing services required. Services such as surveys, repairs and maintenance will have fixed fees. Whereas cut edge corrosion and gutter lining will be price per linear metre (L/M) The table below provides an overview of the estimated cost range for the various industrial roofing services. These estimates can help you plan your budget based on the specific needs and requirements of your industrial roofing project.

| Service | Cost Range |

|---|---|

| Industrial Roof Installation | £54 to £85 per sqm |

| Industrial Roof Maintenance | £250 to £910 |

| Industrial Roof Repairs | £450 to £740 |

| Industrial Roof Survey | £120 to £490 |

| Industrial Roof Leak Repair | £450 to £650 |

| Industrial Roof Replacement | £75 to £164 per sqm |

| Industrial Roof Restoration | £48 to £87 per sqm |

| Industrial Gutter Lining | £45 to £94 per L/M |

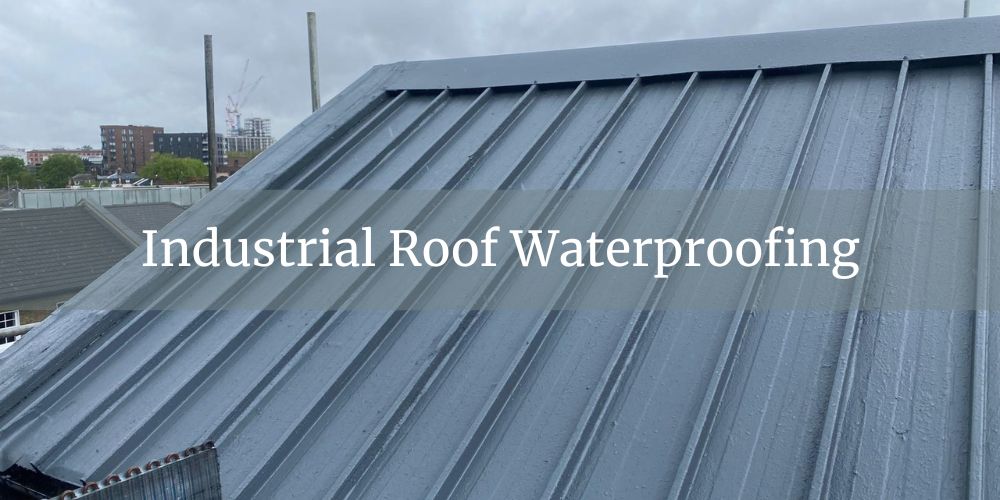

| Industrial Roof Waterproofing | £48 to £110 per sqm |

| Industrial Roof Refurbishment | £46 to £127 per sqm |

| Industrial Roof Recoating | £48 to £92 per sqm |

| Industrial Roof Coatings | £46 to £88 per sqm |

| Cut Edge Corrosion Treatment | £55 to £124 per L/M |

*These estimates are general and actual costs can vary based on specific project requirements, location, and market conditions.